Some pictures of a flatbed platform I made for my Toyota truck, some tool boxes to go under the platform, and a tool I made to easily install the platform's nuts, washers and lockwashers from below.

I wire wheeled all the rusty bits, replaced all the rubber bushings between the bed and frame and ripped the rear arch out of its sockets.

I decided to run all new rear lights and used LEDs this time as well and adding side running lights and reflectors.

I bought 3/4” marine ply for the deck and marked it for the 47 bolts using fiberglass window screen. Fiberglass window screen comes 48 inches wide and doesn’t stretch so I could lay it across the frame, held in place with magnets, and mark through the screen where all the mounting bolts went. It worked great and saved me the hassle of climbing under the truck to mark up through the bolt holes.

The bolts used are Elevator Bolts. Basically a flathead carriage bolt. Elevator bolts have nothing to do with passenger elevators. They are used to hold buckets to conveyor belts for grain elevators, AKA Silos. The bolts are 5/16” x 2” and I made a modified spade bit to countersink for them.

After drilling the holes and coping for the additions to the bed frame, I used a roundover bit on all the edges and then coated both panels with roll-on truckbed liner.

I added a few bits to the bed frame to make it more useful. I added a lug in the middle of the front edge with two 3/4” holes for mounting a winch for pulling items up a ramp. I also added 2 pivot lugs for a future derrick lifting crane. I added some 1/2” bolts to hang 2 aluminum storage boxes for truck straps and such.

I bought the boxes off Amazon and then cut 6 inches off the back. I added some aluminum channel to the tops of the boxes for hanging structure.

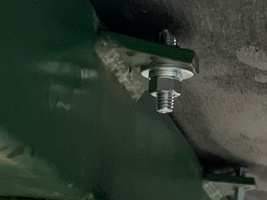

When it came to actually bolting the deck on I had forgotten how tedious it is to get a washer, lock washer and nut onto the overhead bolts. I decided to be clever so I made a tool. I machined a holder that uses a setscrew to lock it to a 1/2” socket. It holds the nut, lock washer and washer in place while you spin them on. It worked perfectly.

I ran a heavy jumper cable under the cab to run the winch and put a connector inside the passenger side storage box.

In the future when I go to build the lifting crane I’ll add an upper winch mount above the cab for lifting the frame. The deck winch will feed over the end of the frame for direct lifting. I just need a way to pick up the 300 to 500 lb steel blocks in my back yard.